eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

Progress and setbacks.

Need to turn some spacers for the leadscrew shaft that's how it was fitted but wasn't obvious when covered in grime. No biggie. Wouldn't have thought that was standard.

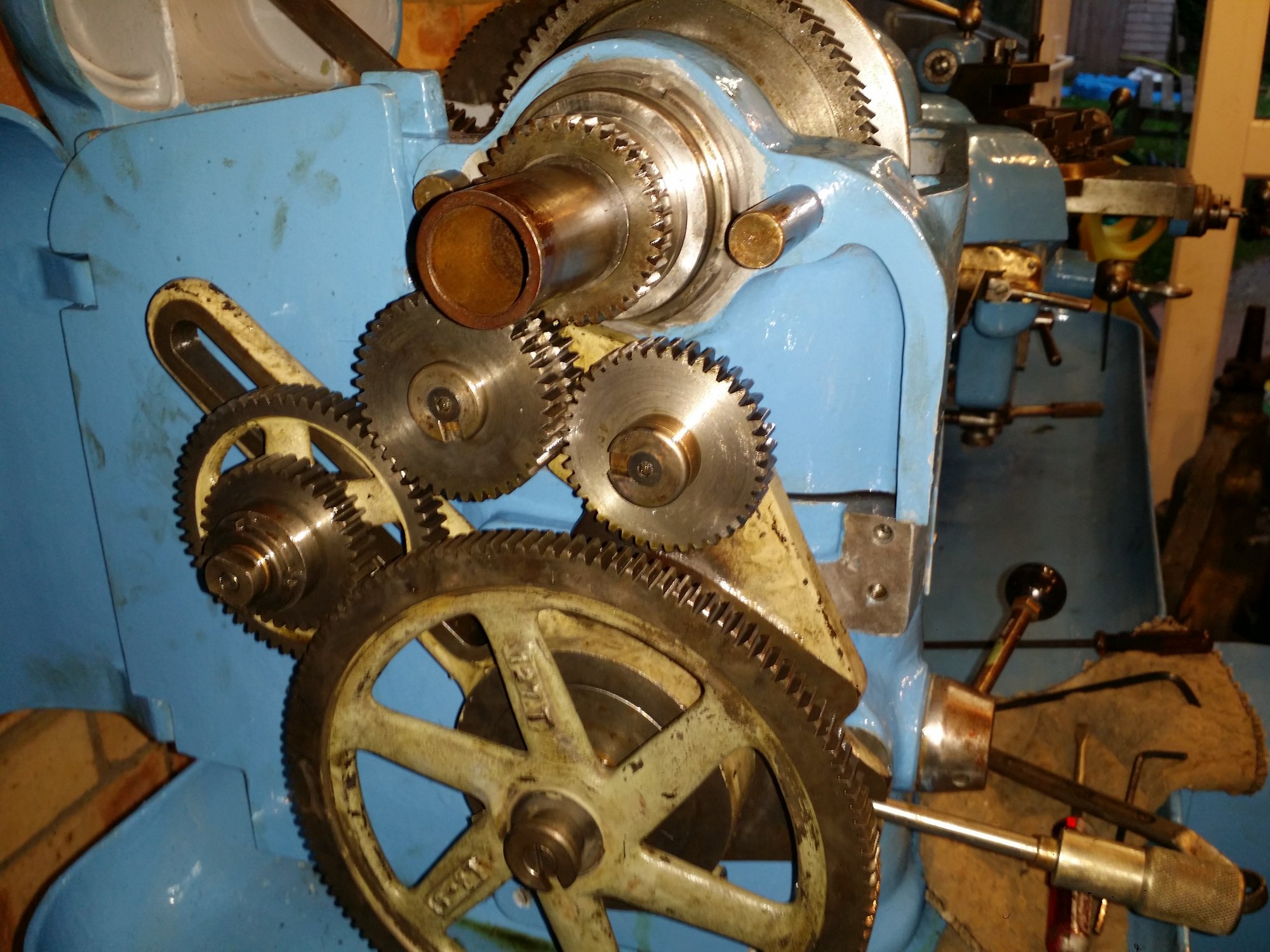

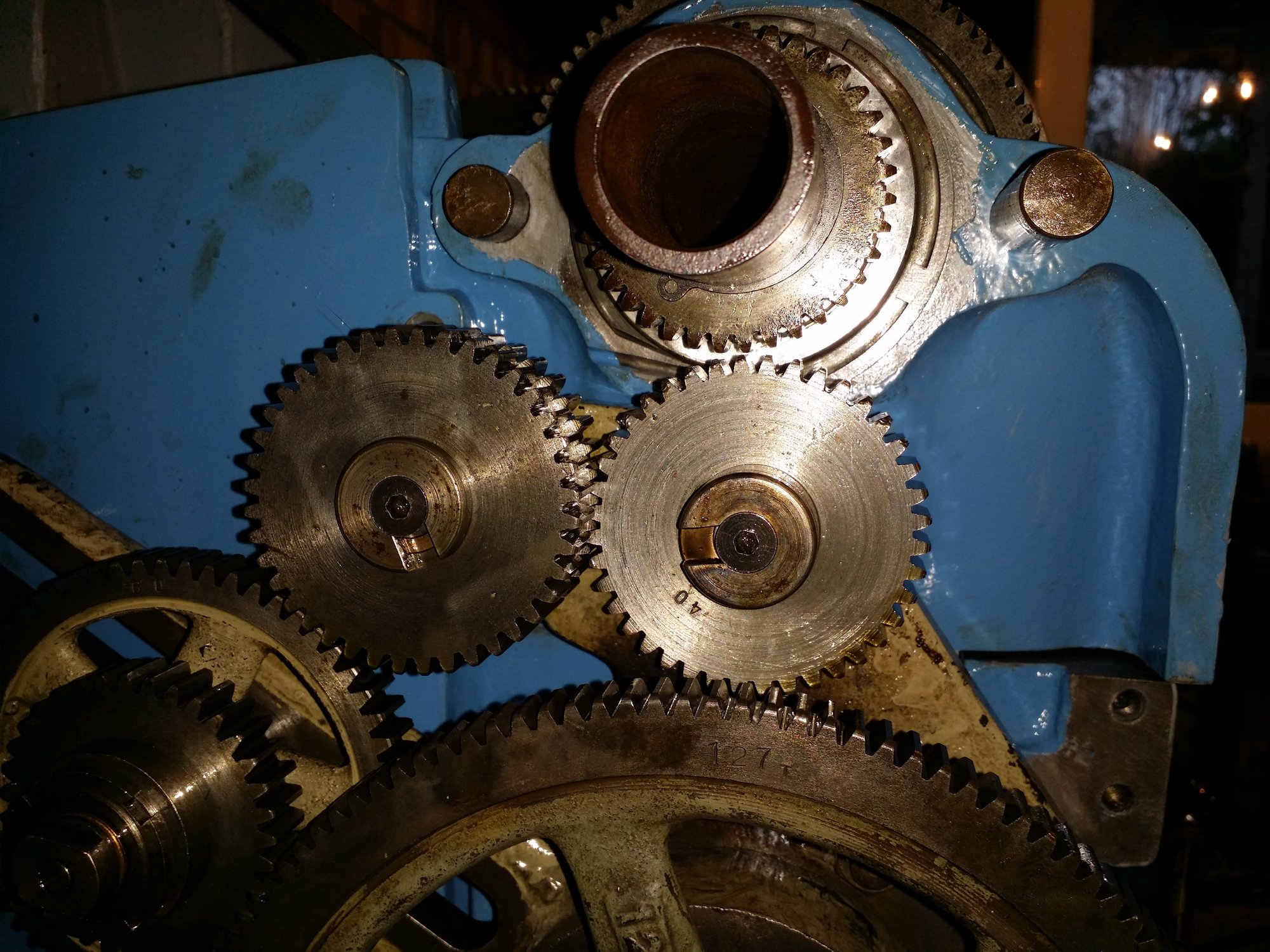

Forward cogs engage well. Reverse cog however has 4mm clearance. Tumbler arm is from a mk 2. Somebody ground off some of the cnut to allow clearance. Wondered if the stud might be cammed to allow small adjustment but haven't had time to punch it out and check. (Doubtful anyway) solution. Bore it out larger and turn a offset spacer. Or find a mk1 arm. Homework required. Won't affect initial use thankfully. Leadscrew later if time allows.

Need to turn some spacers for the leadscrew shaft that's how it was fitted but wasn't obvious when covered in grime. No biggie. Wouldn't have thought that was standard.

Forward cogs engage well. Reverse cog however has 4mm clearance. Tumbler arm is from a mk 2. Somebody ground off some of the cnut to allow clearance. Wondered if the stud might be cammed to allow small adjustment but haven't had time to punch it out and check. (Doubtful anyway) solution. Bore it out larger and turn a offset spacer. Or find a mk1 arm. Homework required. Won't affect initial use thankfully. Leadscrew later if time allows.