You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Smart and Brown model M Mk1

- Thread starter eLuSiVeMiTe

- Start date

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

So out of interest chaps. What are the benifts of using a rear mount tool post over the conventional tool post.

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

Slightly low it was. Packed to height with a 12mm tool blank and one leaf of a butt hinge.Yes, dead on centre, or sometimes fractionally above for blade type, is required. Well fractionally below it would be in your case

il make a one piece spacer for it sometime.

il make a one piece spacer for it sometime.Need to find the 3mm silver steel I bought tomorrow. The wife put it away I thought the mantlepiece was the perfect place to keep it too.

Allen keys I have locking the handles on temporarily kept falling out. Drove me nuts.

Given me a bit of inspiration to get the final bits finished now.

Decided to use your vfd on the lathe once I aquire a motor

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

And it can live on the rear tool post always ready for use.

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,368

- Location

- NE London - UK

The cutting force is tending to lift the cutter. When parting off using the conventional position it's not uncommon for the tool tip to dig in and get dragged under the workpiece, breaking the tool and damaging the piece. With a rear mounted post the force is liftiing the cutting edge so considerably reduces damage due to dig in (that's not to say you can't break the tool, you just need to try harder  )

)

)

)eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

Someone tried hard on my rear tool post. Can see the repair on it on the above photo.The cutting force is tending to lift the cutter. When parting off using the conventional position it's not uncommon for the tool tip to dig in and get dragged under the workpiece, breaking the tool and damaging the piece. With a rear mounted post the force is liftiing the cutting edge so considerably reduces damage due to dig in (that's not to say you can't break the tool, you just need to try harder)

Not the tool post but the bolt on t slot underneath

Seadog

Save the planet. It's the only one with rum!

- Messages

- 12,368

- Location

- NE London - UK

Surely when it is upside down then the same can happen on the rear, ie it lifts and can get dragged in. Main benefit to my mind is gravity clears the chips.

I can see you point Hood. It would depend on whether there is any vertical movement in the saddle. With the Boxford, my one at least, slack in the retaining strip under the sear is taken up by Thackeray washers allowing a small amout of lift. This may or may not apply to other lathes.

Pete.

Member

- Messages

- 14,572

- Location

- Kent, UK

So out of interest chaps. What are the benifts of using a rear mount tool post over the conventional tool post.

I once saw an animation that explained it very well. Basically when the blade is overloaded and forced downward it putting a tremendous amount of spring into the sliding assemblies by compressing all the moving joints together between the work and the lathe bed. Eventually the pressure becomes so great that the tool is forced upwards sharply then the cycle repeats which is how you get parting chatter. Using the rear tool post and the tool upside down does 2 things - it removes 3 flexible elements (the tool post, the compound slide mount and the compound slide dovetail) making the tool post more rigid and less likely to dig in plus instead of forcing everything down in towards the bed it tends to put some lift on the carriage and cross slide which is - for want of a better term - a much less harsh action. It's still a lot of force imparted to lift the saddle and apron off the ways but it's not inducing huge spring forces in the assembly.

God mode restorations

Member

- Messages

- 8,152

- Location

- uk colchester

Thanks Pete.I once saw an animation that explained it very well. Basically when the blade is overloaded and forced downward it putting a tremendous amount of spring into the sliding assemblies by compressing all the moving joints together between the work and the lathe bed. Eventually the pressure becomes so great that the tool is forced upwards sharply then the cycle repeats which is how you get parting chatter. Using the rear tool post and the tool upside down does 2 things - it removes 3 flexible elements (the tool post, the compound slide mount and the compound slide dovetail) making the tool post more rigid and less likely to dig in plus instead of forcing everything down in towards the bed it tends to put some lift on the carriage and cross slide which is - for want of a better term - a much less harsh action. It's still a lot of force imparted to lift the saddle and apron off the ways but it's not inducing huge spring forces in the assembly.

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

Advice sought.

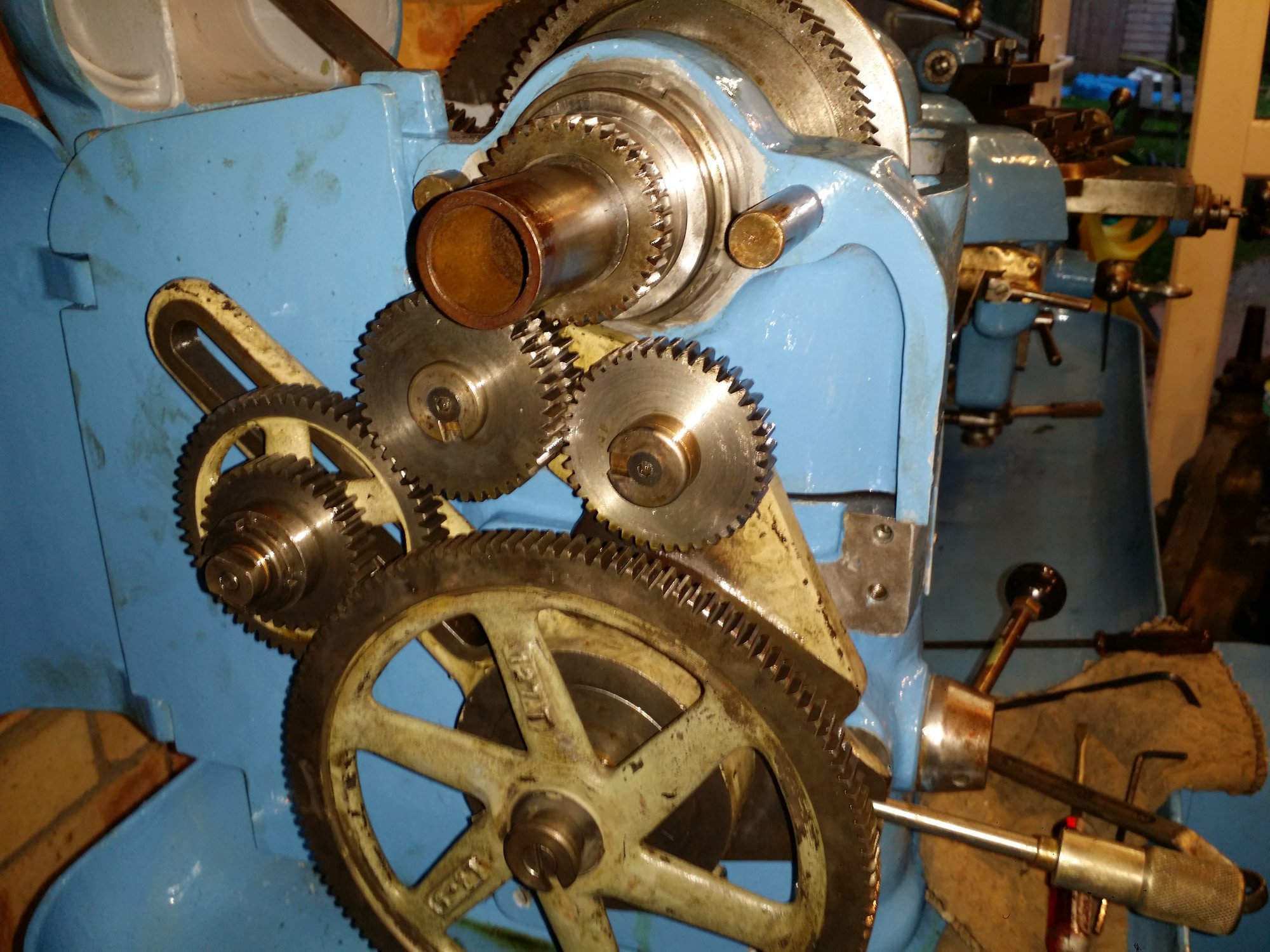

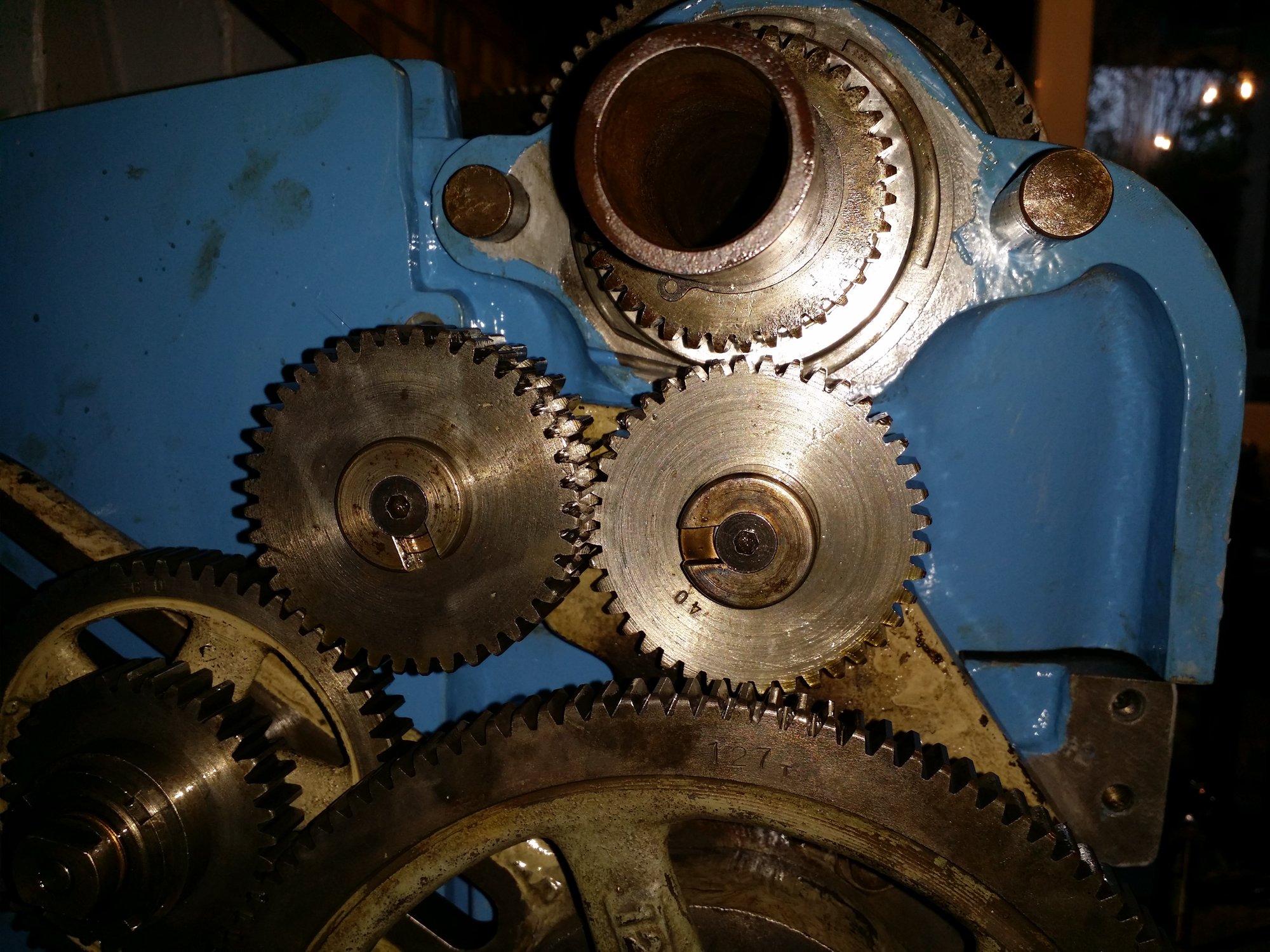

So this is my issue with the tumble reverse.

Bracket is from a mk2 I've got 2 thirds of the oriGinal but it's never going to be usable.

Would it be feasible to get a new spindle gear made up. 5mm or so on the diameter would allow the tumblers to work without modifications and save me headaches.

Not had the opportunity to cut threads yet how would the bigger spindle gear effect screw cutting abilities

Reverse engages fine. Forward falls just shy

So this is my issue with the tumble reverse.

Bracket is from a mk2 I've got 2 thirds of the oriGinal but it's never going to be usable.

Would it be feasible to get a new spindle gear made up. 5mm or so on the diameter would allow the tumblers to work without modifications and save me headaches.

Not had the opportunity to cut threads yet how would the bigger spindle gear effect screw cutting abilities

Reverse engages fine. Forward falls just shy

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

Original bracket is in two pieces and I don't have the second piece Unfortunately.It doesn't look like the tumbler teeth match the change gear teeth. Can you post up OD and tooth count for those because they look like they are different DP.

Why can't you use the original tumbler?

Can't say I'd noticed them not meshing properly il have a look tomorrow and double check the pd. Possibly the odd angles of the pics.

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

Il have a nosey tomorrow and do the math and see if I can find something suitable to modify.

Worst case il have to move the tumbler stud.

Worst case il have to move the tumbler stud.

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

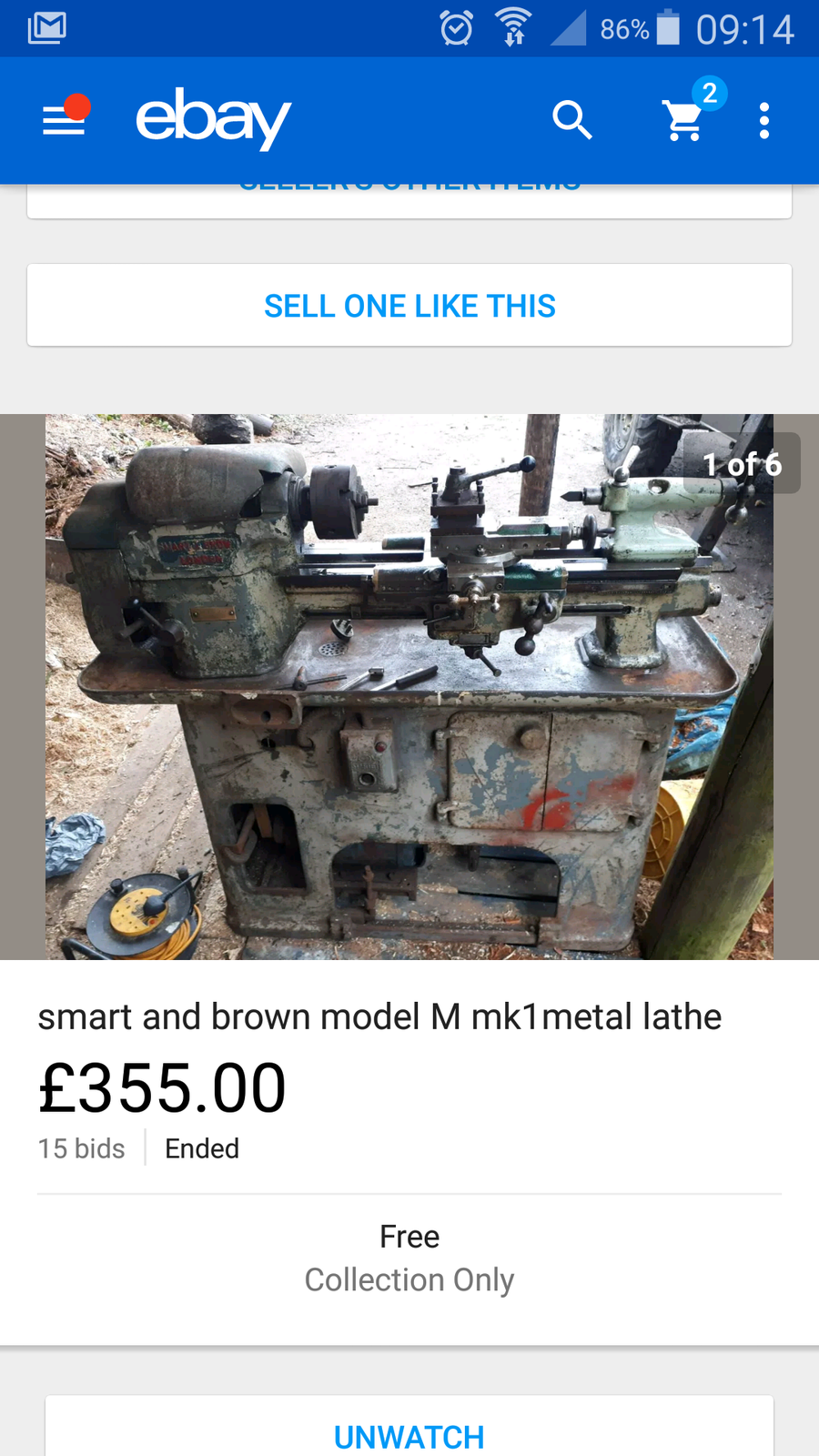

Hmm. Was watching this. Was at 140 yesterday afternoon. Planned to strip what I needed and sell the rest on

Wasn't expecting it to get anywhere near that price.

Paid £220 for mine in better condition.

Wasn't expecting it to get anywhere near that price.

Paid £220 for mine in better condition.

Dieselman 63

Forklift Certified

- Messages

- 5,681

- Location

- Wellington, New Zealand

What a wreck - it's always sad to see cracked cast. It really shouldn't be possible, you wonder what they've been doing to break it... Also this one is missing the grilled motor door too!

eLuSiVeMiTe

Member

- Messages

- 16,444

- Location

- ......

Yup. Would have given 200. Taken what I needed faceplate chabgewheels tailstock etc and sold the rest on for a reasonable price to recoup my money.That's a piece of scrap or a boat anchor..

Cabinet would be grand for similar size Lathes. Rock solid Someone must have been desperate for parts