finyuk2005

Member

- Messages

- 745

I keep meaning to get one of those, they do save a lot of mess!

where did you get yours?

I keep meaning to get one of those, they do save a lot of mess!

I keep meaning to get one of those, they do save a lot of mess!

where did you get yours?

www.dwtoolshop.com

www.dwtoolshop.com

I've just been looking at them. What make is it?

SeleayI've just been looking at them. What make is it?

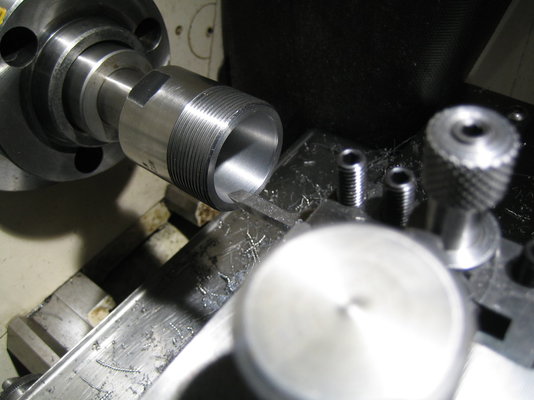

Oil sucked out a replaced, this is a tool I wish I bought sooner

. Lets see how hard it is, started with Carbide boring bar (don't think I really needed to

. Lets see how hard it is, started with Carbide boring bar (don't think I really needed to } and finished with HSS tool for the finishing cuts

} and finished with HSS tool for the finishing cuts

My old splitty back in 74 didn’t have a gutter to attach a roof rack, I swept most of it up and put it in the dustbin!Got the ladder back from the galvanisers Friday,so after the usual fettling,found some wood with radiused arris’ to protect the poor paint on the gutters.Note the stowing area behind the pop top.

Damn! just noticed 2 rungs off parallel.doh.

View attachment 309321View attachment 309322

Vee-blocks will show a problem - just can't measure it correctly - runout, circular or total, is relative to the axis, which vee-blocks can't give you. Caused us some enormous problems recently - not helped by the talyrond going in the skip some years ago . . . not that many (any?) of us knew how to use it correctly!I know a seven sided coin will actually exhibit a considerable amount of runout in a 90 degree V block.

Your confusion is due to the (well known) constant height radius, that only works diametrically opposite to a single point of contact. In a V block it will display considerable runout.

As for the general principle that a V block will not "necessarily" always reveal runout in a shaft, I concur. However in this case, it certainly did.

Vee-blocks will show a problem - just can't measure it correctly - runout, circular or total, is relative to the axis, which vee-blocks can't give you. Caused us some enormous problems recently - not helped by the talyrond going in the skip some years ago . . . not that many (any?) of us knew how to use it correctly!

Inspection in vee blocks was supposedly giving us runout well within tolerance - but actually in use it was pants for what we needed. Getting it checked in a proper chuck/collet set-up showed it up straight away. Learnt something after 25 yrs of assuming I already knew it.

Wasn't the only part of my knowledge of BS GD&T that was blown apart!

Put a 50 pence piece in a vee block and clock it as it you rotate it . . . it'll show bugger all run-out . . .

I dripped Basso on the thread & nut mating face on my chuck as well as back file the slots in all my collets to a tiny chamfer for it was well past hand sticky in parts of the thread & collet slot edges to tighten things up .My ER32 2MT chuck wasn't very good at holding milling cutters in the Centec and the nut only screwed on one thread before it started to tighten the collet! So I measured the taper and found it was 2mm smaller diameter than any of the other ones. Lets see how hard it is, started with Carbide boring bar (don't think I really needed to

} and finished with HSS tool for the finishing cuts

.View attachment 309308View attachment 309309

My sisters combi boiler went wrong so the first part i looked at was listed as a common fault, changed the relay on it for £2 rather than pay £50 for a new one, sadly not cured it bit at least i know it is not that part now

View attachment 309717