You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

mr migwire

It's more fun with metal.

- Messages

- 1,877

- Location

- fife

mr migwire

It's more fun with metal.

- Messages

- 1,877

- Location

- fife

Just ask @northwest to borrow the real thing for the weekend I'm sure he's got several

Cracking job though.

northwest

Searching for the Holy Grail.........

- Messages

- 6,663

- Location

- Manchester UK

Just ask @northwest to borrow the real thing for the weekend I'm sure he's got several

Two actually and would have been quite happy to loan you one, or both as long as they find their way back, sadly both are deactivated but ideal for this. Nice effort by the way.

Dcal

Member

- Messages

- 4,093

- Location

- Antrim Northern Ireland

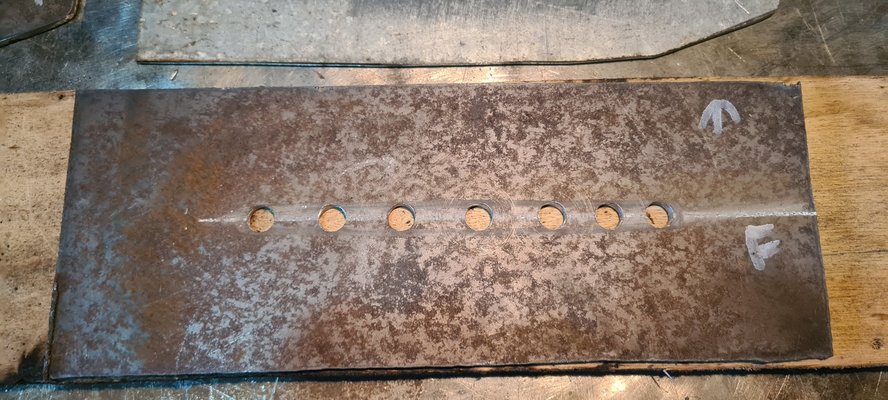

At the weekend I finally made a modification to my MTD ride on to make it easier to change the drive belts.

These old mowers have a really strong spring that keeps tension on the variator.

Every time I have to work on the variator, getting the spring back on is a pain and I haven’t been able to come up with a tool that make the job any easier.

The spring attached to a hook that bolts to the chassis with 2 number 5/16 bolts

Anyway I was giving the mower some TLC and changed the drive belts

Instead of fighting with the spring (again) I came up with this method of tensioning it after installing it.

I cut a slot in the chassis in line with the original bolt holes, which are in line with the two bolt holes above the slot.

I then welded nuts and some flat bar to the spring hook and made a doubler plate to reinforce the chassis and to provide a slide for the modified spring hook.

Then it was a simple job of welding the doubler plate to the chassis.

It was blowing a gale and stick was an easier option than clearing out the garage to get it inside and mig or tig it, however it turns out welding 5mm plate to the 1.5mm chassis with 2.5mm 7018 is the limit (or beyond the limit) of my arc welding skills but it will do for now.

It's also why I just bought the 1,6 rods from @nickk which would have made it a lot easier and less holey.

With the slide fitted I connected the spring to the hook at the limit of travel (least tension) with a pair of vice grips, then tensioned it with a F clamp.

When it was fully tensioned I just tightened the (now) M8 bolts and job done.

Bit of a flaff but easier, probably quicker and certainly less sweary than trying to stretch the spring to install it. Also it will be done for the next time.

I was going to make an adjuster with an M8 bolt, but I don't think it's necessary as the F clamp worked a treat.

These old mowers have a really strong spring that keeps tension on the variator.

Every time I have to work on the variator, getting the spring back on is a pain and I haven’t been able to come up with a tool that make the job any easier.

The spring attached to a hook that bolts to the chassis with 2 number 5/16 bolts

Anyway I was giving the mower some TLC and changed the drive belts

Instead of fighting with the spring (again) I came up with this method of tensioning it after installing it.

I cut a slot in the chassis in line with the original bolt holes, which are in line with the two bolt holes above the slot.

I then welded nuts and some flat bar to the spring hook and made a doubler plate to reinforce the chassis and to provide a slide for the modified spring hook.

Then it was a simple job of welding the doubler plate to the chassis.

It was blowing a gale and stick was an easier option than clearing out the garage to get it inside and mig or tig it, however it turns out welding 5mm plate to the 1.5mm chassis with 2.5mm 7018 is the limit (or beyond the limit) of my arc welding skills but it will do for now.

It's also why I just bought the 1,6 rods from @nickk which would have made it a lot easier and less holey.

With the slide fitted I connected the spring to the hook at the limit of travel (least tension) with a pair of vice grips, then tensioned it with a F clamp.

When it was fully tensioned I just tightened the (now) M8 bolts and job done.

Bit of a flaff but easier, probably quicker and certainly less sweary than trying to stretch the spring to install it. Also it will be done for the next time.

I was going to make an adjuster with an M8 bolt, but I don't think it's necessary as the F clamp worked a treat.

That's a crime against a perfect bit of engineering unchanged for over 100 years...sadly both are deactivated

selectedgrub

Member

- Messages

- 3,504

- Location

- New Zealand

While eating out at this flash restaurant I took out my felt tip pen and did doodle on their plater.

I called it Devil's food, like that song from Alice Cooper.

After all, once your finished eating breasts and thighs all you got left is a greasy box to put your bone in.

I called it Devil's food, like that song from Alice Cooper.

After all, once your finished eating breasts and thighs all you got left is a greasy box to put your bone in.

selectedgrub

Member

- Messages

- 3,504

- Location

- New Zealand

Is there anything left on this ride that's factroy?

Subtle class.

Hood

I am obsessed.

- Messages

- 17,975

- Location

- Carnoustie, Scotland

Lots, in fact everything is standardIs there anything left on this ride that's factroy?

selectedgrub

Member

- Messages

- 3,504

- Location

- New Zealand

Ah yes. Dressed up.

I have heard of this term from the yanks.

Not really my cup of tea.

I have heard of this term from the yanks.

Not really my cup of tea.

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,074

- Location

- Sevenoaks, UK

I presume you're a member of a re-enactment group etc or how do you otherwise get round the draconian VCRA legislation for having made a replica weapon?

Makes me want to carry on with my abandoned Stirling replica!

DAPPH

as dyslexik as I'm daft

- Messages

- 7,329

- Location

- Near to Cross Hands Llanelli SouthWales GB

Simple channels of folded marine grade stainless steel having internal facing folded safety edges as strengthening & simple end stops .I've wasted some tig rods and solder paste.

View attachment 342754

It's a mock up of a spice rack, the plan was to make up two "sheets" like this, have them upright with some more rods to space them apart and the jars would fit in the hexagonal slots, probably with a third grid behind it to keep them falling out of the back.

View attachment 342755

This mockup has proven its a crap design. A square grid would give about 15 percent denser packing of the jars and would be much easier to make, I thought the hexagonal arrangement would look cool but now I've got it in front of me, I'm not that keen anyway.

If anyone's got any good ideas for spice storage I want to hear them. The main requirement is it has to be dense, I've got 53 jars (And counting) and a tiny kitchen.

Site them one above the other screwed to the walls or use super sticky double sided tape on highly volatile spirit cleaned surface to put them on the fridge door or inside cupboards on the doors . Make the channels just deep enough so you can read most of the labels & that they wont fly out if the door is close a bit quickly . Set the next row above it so you can easily remove a jar when needed

DAPPH

as dyslexik as I'm daft

- Messages

- 7,329

- Location

- Near to Cross Hands Llanelli SouthWales GB

Every time the rider put the lights on........ the battery exploded due to the dead short ?Ah yes. Dressed up.

I have heard of this term from the yanks.

Not really my cup of tea.

Maker

Most folk just call me; Orange Joe

- Messages

- 10,679

- Location

- Keeler crater

A folded channel would do if I had a folder, and some stainless.Simple channels of folded marine grade stainless steel having internal facing folded safety edges as strengthening & simple end stops .

Site them one above the other screwed to the walls or use super sticky double sided tape on highly volatile spirit cleaned surface to put them on the fridge door or inside cupboards on the doors . Make the channels just deep enough so you can read most of the labels & that they wont fly out if the door is close a bit quickly . Set the next row above it so you can easily remove a jar when needed

I was using tig rods because I already had it, and because the old rack was made of wire, but I do think it looks quite cool so I might stick with it. Stuck on the fridge door looks a bit ugly imo, same with using the kitchen door as someone said earlier (Plus it's a bifold). I did look at the inside of a cupboard door but it would take up a precious couple of inches at the front of the cupboard. I'll have another crack at it next time I feel the urge, for now I've put the 21 I use most back on the old rack and the rest are in a box in the hall and need tipping out on the floor to find the one I'm looking for.

I was using tig rods because I already had it, and because the old rack was made of wire, but I do think it looks quite cool so I might stick with it. Stuck on the fridge door looks a bit ugly imo, same with using the kitchen door as someone said earlier (Plus it's a bifold). I did look at the inside of a cupboard door but it would take up a precious couple of inches at the front of the cupboard. I'll have another crack at it next time I feel the urge, for now I've put the 21 I use most back on the old rack and the rest are in a box in the hall and need tipping out on the floor to find the one I'm looking for.Brad93

Member

- Messages

- 19,417

- Location

- Essex, United Kingdom

That's fantastic

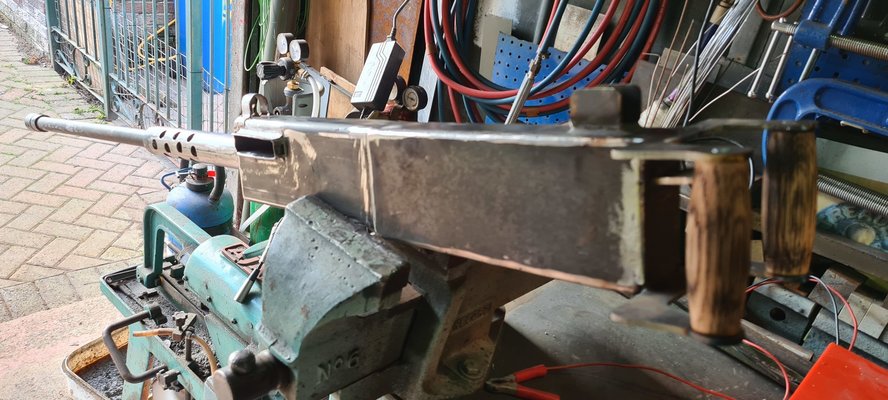

The new saw in the mill has been in use for 2 days,today they crashed the de stoning cutter arm into the log and bent it,it’s a bit weak,a 60 mm shaft,only supported 1 side of the 100/40 box arm,I’ve suggested a reinforcement plate on the one side(it’s not possible on both sides),as I can see it happening again,problem is ,it deformed the box.

Onoff

In the land of the unfinished project I am King!

- Messages

- 13,074

- Location

- Sevenoaks, UK

You should knock at number 61, they'd probably have one off of you.

The new saw in the mill has been in use for 2 days,today they crashed the de stoning cutter arm into the log and bent it,it’s a bit weak,a 60 mm shaft,only supported 1 side of the 100/40 box arm,I’ve suggested a reinforcement plate on the one side(it’s not possible on both sides),as I can see it happening again,problem is ,it deformed the box.

I'd be considering what happens if I reinforce this, and they do it again? What bigger, harder to get off, harder to fix, more expensive part will they bust?

Might be worth actually making that bit weaker so it shears off - make it demountable so the spare they bought at the same time (ha!) can quickly be fitted.