You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stuff you have made today

- Thread starter God mode restorations

- Start date

Parm

Respect The Sound System

- Messages

- 17,917

- Location

- Towcester

@Parm

@Chillitt

@slim_boy_fat

@angellonewolf

In my mad, manic and calm tidy up, this was uncovered.

View attachment 210993

So I acquired this bundle.

View attachment 210994

So, put it together and what do you get?

www.youtube.com/watch?v=z3QeYtv1OPs

@mrsbruce almost suitable for you.

View attachment 210995

The shaft was old, but been in a workshop for a while.

Hand scarper had most of the dirt off. A polish on the lathe.

The head was wire brushed and polished.

View attachment 210996

Yes, I have saved another hammer.

But where is mine? I want a hammer

angellonewolf

Member

- Messages

- 8,580

- Location

- bristol england

^^^^^you forgot stamping feet

I think they should be ok with a little JB Weld.

It’s the big end of the no.5 connecting rod. The piston was so stuck that I flared the end of the rod out by beating on it.

Fortunately all the pieces I need are intact.

View attachment 211143

Did the bores not get badly scored getting those pistons out? Or is this going to be converted into a coffee table!

The_Yellow_Ardvark

https://www.death-clock.org/

- Messages

- 19,912

- Location

- Going Away.

^^^^^you forgot stamping feet

But unlike one on here. @Parm will not go running and crying to a Mod on here.

Tupers

Member

- Messages

- 954

Did the bores not get badly scored getting those pistons out? Or is this going to be converted into a coffee table!

The bores aren’t too bad but as you’ve guess it’s becoming a coffee table.

Hopefuldave

Intergalactic pot-mender

- Messages

- 2,545

- Location

- The Shed of Danger, surrey, England

The bores aren’t too bad but as you’ve guess it’s becoming a coffee table.

:'(

Dave H. (the other one)

Hood

I am obsessed.

- Messages

- 17,478

- Location

- Carnoustie, Scotland

Did she make one for herself as well?OH acquired 2 old bread trays from the local food bank where she volunteers, so a spot of repurposing has turned one of them into a jewellery holder in her dressing room.

View attachment 211242

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,622

- Location

- North Kent, UK

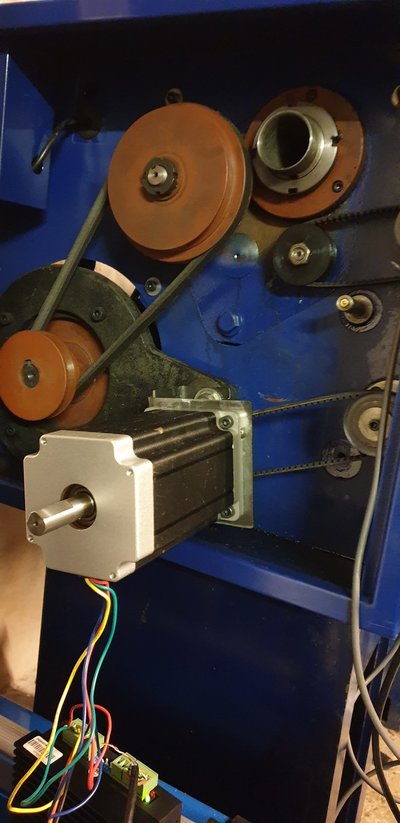

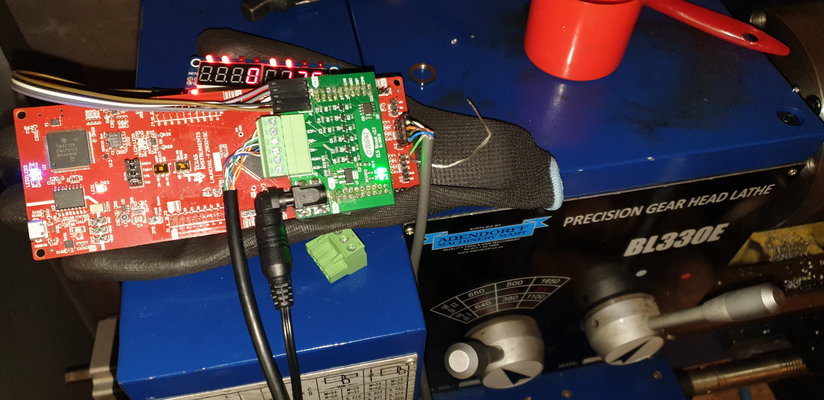

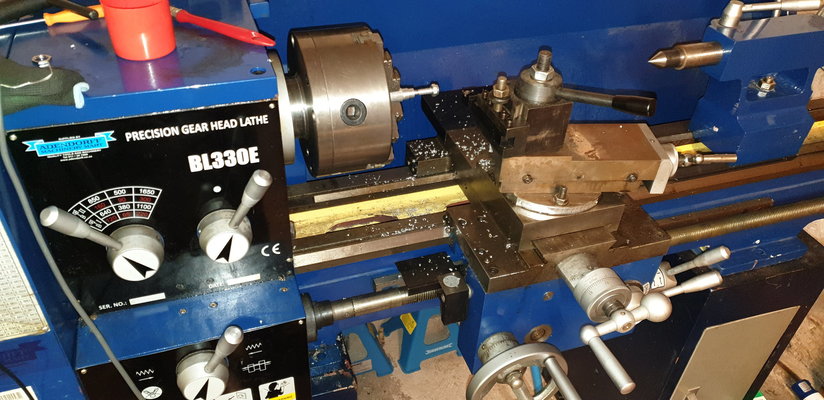

Turned my Lathe into electronic screw - it works need to now make it all nice looking

View attachment 211238 View attachment 211239 View attachment 211240

Nice job.

How will you sync it for screw cutting?

Farside

Badly Welded Man

- Messages

- 5,956

- Location

- Ireland

The bores aren’t too bad but as you’ve guess it’s becoming a coffee table.

NOOOOOOOOOHHHHHHHHHHHHHHHHH..................

Did she make one for herself as well?

It's just a rumour, why would I need to hold a lily?

.

.Edit: "Hold"??? Should have said gild...

Last edited:

Maker

Most folk just call me; Orange Joe

- Messages

- 10,553

- Location

- Keeler crater

Glad it wasn't just me who thought that.Are they handcuffs?

Looks like something Spencer's misses might have at first glance.

Looks like something Spencer's misses might have at first glance.

I just leave the half nut engaged and reverse the stepper motor after backing out the cutterNice job.

How will you sync it for screw cutting?

Johnnybravo

Member

- Messages

- 3,640

- Location

- Northiam

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,622

- Location

- North Kent, UK

Some big swarf. Haven’t used my 62mm drill in awhileView attachment 211285

Jeez! How big is your tailstock????

Windy Miller

Semi-Professional Potterer!

- Messages

- 3,622

- Location

- North Kent, UK

I just leave the half nut engaged and reverse the stepper motor after backing out the cutter

How do you sync the tool travel speed with the rotation of the workpiece for a given thread pitch?

The electronics has an encoder which is run off the head stock in the back of the lathe which then calculates the stepper motor speed based on the gear ration and stepper micro steps setup on the Stepper driver and in the controller. this is not my design but rather https://github.com/clough42/electronic-leadscrew/wiki - I just followed alongHow do you sync the tool travel speed with the rotation of the workpiece for a given thread pitch?