ajlelectronics

Forum Supporter

- Messages

- 10,048

- Location

- Gloucester, England

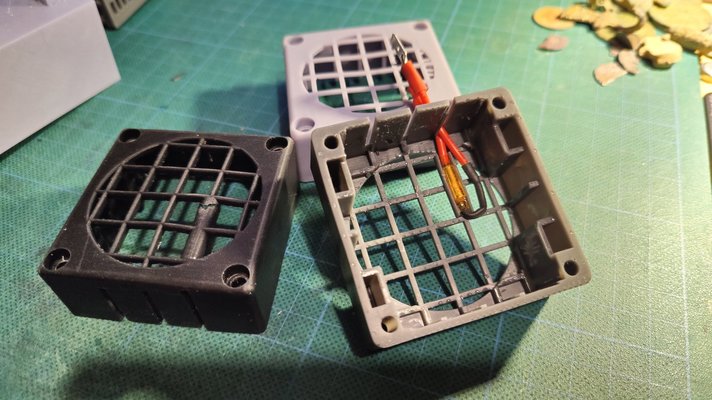

Scimitar switch bezel for aftermarket switches.

What shore TPU are you using?Some production exhaust mountings on the Bambu, running a fair speed now - up to 15mm/s of flow vs the standard profiles of 3.6-ish.

That's a 4 hour print on 200g of material, which is probably as fast or faster than most print normal PLA.

Got a bit of stringing at the end there there's a bit of a bug with my printer I'm trying to sort out with support - might just be a faulty SD card, got a new one on the way. It pauses for a few seconds on short layers before travelling, not so great for soft foam materials that ooze out. But it just pulls off the part easily so it's not really an issue atm.

It's not quite as fast as my other dual extruder printer I use for TPU, but then that one is setup only for flexibles like TPU and PTCPE and can't do stuff like abrasive materials, and is slow on normal materials because of the way the extruders are optimised for soft filaments, etc - but it's close enough I can run both in sync now and just unload and prep them in a staggered pattern.

You are lucky it reaches 80degrees. LolFirst time printing with PETG. Seems a better finish and more robust than PLA, and a lot less faff than ABS.

Only downside is my bed takes ages to get up to 80C. No more PLA for me!

View attachment 436044

Blimey how many do you have and how much room? When I made an admittedly 'made from whatever was lying around' enclosure it takes up soo much roomI was sad enough my new one only does 100 and not 120 like my others. I think less than that I'd be crying

150-160c is the plan for minimum on the next one

I can smell burnt fingers in your future.I was sad enough my new one only does 100 and not 120 like my others. I think less than that I'd be crying

150-160c is the plan for minimum on the next one

Try putting a bit of packing foam over the bed whilst it warms up. Speeds things up quite a lot.First time printing with PETG. Seems a better finish and more robust than PLA, and a lot less faff than ABS.

Only downside is my bed takes ages to get up to 80C. No more PLA for me!

View attachment 436044

I have an enclosure for it, too - bought it for ABS but it's too big and clumsy so I took it off. Probably should put it back on...Try putting a bit of packing foam over the bed whilst it warms up. Speeds things up quite a lot.

Obviously you have to remove it before the print starts

A 'proof of concept' 150W heater for Jupiter resin printer. Nothing too clever, a resin printed case and heater shroud, an off the shelf heater, fan and STC1000 temperature controller...

View attachment 434444

I love practical simple solutions to problemsThe great thing about having a 3D printer isn't just that you can use it to make complex, new, otherwise-difficult-to-obtain items, but that you can also use it to address easy problems!

We have a rolling-week calendar in the kitchen that helps our family of three understand where everyone is over the next few days. The problem is that you can get good whiteboard markers without magnets, and rubbish markers with magnets.

So... how to combine the two?

Easy - three neodyne magnets, 15 minutes of PETG and some superglue gets us from this:

View attachment 437092

To this!

View attachment 437093

View attachment 437094

And they just friction fit to the end of the pens so I can reuse them when we replace the pens.

Where do you get the quality pens from?The great thing about having a 3D printer isn't just that you can use it to make complex, new, otherwise-difficult-to-obtain items, but that you can also use it to address easy problems!

We have a rolling-week calendar in the kitchen that helps our family of three understand where everyone is over the next few days. The problem is that you can get good whiteboard markers without magnets, and rubbish markers with magnets.

So... how to combine the two?

Easy - three neodyne magnets, 15 minutes of PETG and some superglue gets us from this:

View attachment 437092

To this!

View attachment 437093

View attachment 437094

And they just friction fit to the end of the pens so I can reuse them when we replace the pens.