My experience is that getting the printer is the easy bit.Sat on the fence here, would like a 3D printer for mold making but ultimately the only one big enough for my needs is the 500x500mm Creality. Ed is convinced the print time on something like a bell housing would take too long and it would be better off subbed out to a company with a commercial machine, at £500 ish wondering if I should give it a go.

Bob

Yes it does take time printing items but you soon get used to waiting and getting on with other stuff.

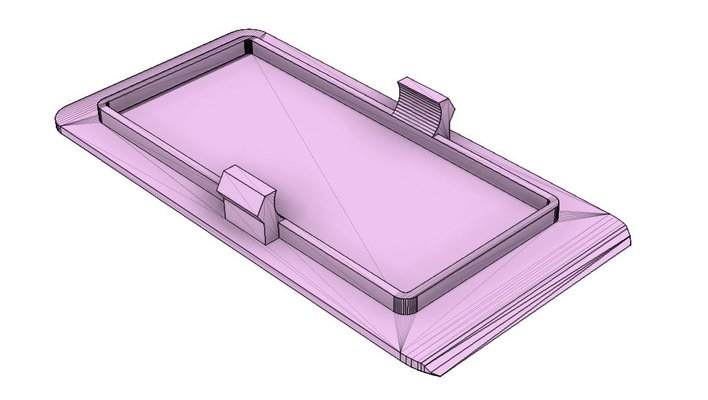

The biggest drawback from my side of things is creating the model . It's one thing jumping on thingiverse and printing.....but another adjusting to allow for shrinkage etc.

If they draw it as a parametric object and give you the file you can alter it...assuming of course you know how.

I was lucky to have help from a couple of people on here and found it very hard to convey what I needed as it was hard to explain without a drawing. And even then everytime it was fitted to the car we kept finding little bits catching that needed rework.

If I knew fusion it would have made life much easier but in the end it showed me the need to learn Fusion is more important than the printer.

forgive the hacked Ali block that would make @doubleboost cringe but I got fed up of taking time finishing things only to have to re do it because of changes and errors while learning to mill. (Such as not subtracting half the edge finder) even though I had read about it many times. Lol

forgive the hacked Ali block that would make @doubleboost cringe but I got fed up of taking time finishing things only to have to re do it because of changes and errors while learning to mill. (Such as not subtracting half the edge finder) even though I had read about it many times. Lol

.

.