- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- CAD/CAM, 3D Printing and Laser Cutting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Handy 3d prints for the workshop

- Thread starter BelgiqueB

- Start date

Bladevane

Forum Supporter

- Messages

- 1,035

- Location

- Harwell, Oxon

What Slicer are you using? In Prusa Slicer there is an option to paint on supports as well as automatic selection. Looks like a judicious use of the former might help you. I've printed quite a lot with both options and they are dead easy to remove after printing.

carbon

Member

- Messages

- 2,943

- Location

- S. Glos. U.K

Slowing the print speed down and reducing the layer height may help, or split the print in half and either bond the two halves together or incorporate some mechanical fixing points in the arms.

Split parallel to the surface, then the support inside the cups should work as it starts large then reduces in size

Split parallel to the surface, then the support inside the cups should work as it starts large then reduces in size

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,127

- Location

- Sevenoaks, UK

With a dual head printer you could use water dissolvable support material.

Yep, discussed that with No.1 son earlier.

Slowing the print speed down and reducing the layer height may help, or split the print in half and either bond the two halves together or incorporate some mechanical fixing points in the arms.

Split parallel to the surface, then the support inside the cups should work as it starts large then reduces in size

Just done that, better but not perfect. Plan to use mitre bond then slide the two bits together on a 6mm hex shaft to align:

This. It's the overhang that's the problem. Set it to automatic supports and you're good to go. They're easy to remove by hand.What Slicer are you using? In Prusa Slicer there is an option to paint on supports as well as automatic selection. Looks like a judicious use of the former might help you. I've printed quite a lot with both options and they are dead easy to remove after printing.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,127

- Location

- Sevenoaks, UK

What Slicer are you using? In Prusa Slicer there is an option to paint on supports as well as automatic selection. Looks like a judicious use of the former might help you. I've printed quite a lot with both options and they are dead easy to remove after printing.

Cura.

daedalusminos

Member

- Messages

- 2,264

- Location

- Norwich

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,127

- Location

- Sevenoaks, UK

I hate supports - personally I'd rethink construction, I've made a few anemometers and always printed them with separate arms...

View attachment 279343

Like that idea, I shall investigate redoing the design. Tbh I just copied the commercial head.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,127

- Location

- Sevenoaks, UK

What layer height are you using?

0.3mm.

|Send me the STL mate. I will run it through my printers and see what it prints like!Yep, discussed that with No.1 son earlier.

Just done that, better but not perfect. Plan to use mitre bond then slide the two bits together on a 6mm hex shaft to align:

View attachment 279338

View attachment 279339

View attachment 279340

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,127

- Location

- Sevenoaks, UK

|Send me the STL mate. I will run it through my printers and see what it prints like!

Cheers for that. I've emailed it. Be very interested to see how it prints in one hit. Just trying here at the mo printing one half at 0.1mm layer height. Looks a "finer" print for sure.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,127

- Location

- Sevenoaks, UK

Tried printing a DeWalt 20V battery to Makita tool adapter. Unusual in that it utilises the top half of a dead Makita LXT battery. This is for a mate who has a lockup with no power. The plan is to use his works DeWalt drill battery on one of the cheapo Makita grinder clones.

First problem I can't find my T? security bit screwdriver to take the battery apart!

I got the .stl from here:

www.thingiverse.com

www.thingiverse.com

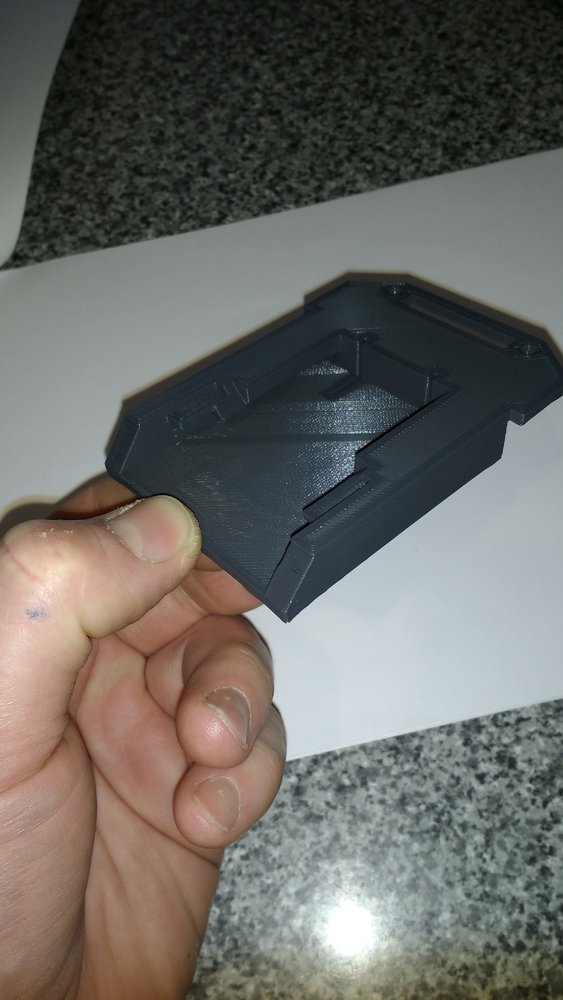

Printed in grey RS Pro PLA. I don't have a modern DeWalt battery & tool to compare it with but it appears to have a wafer thin "infill" section where my thumb is in the two pictures:

The pretty side:

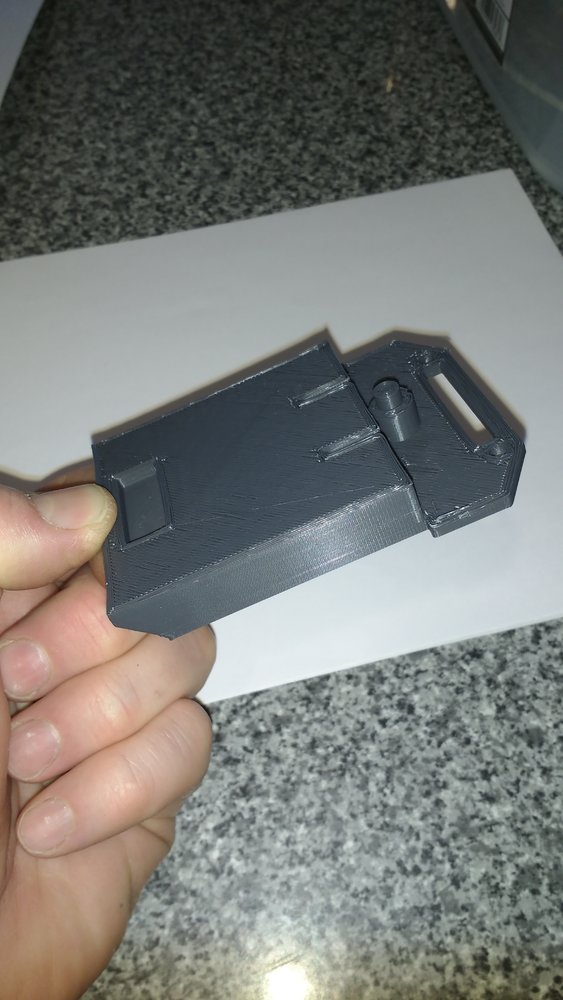

The side that was supported:

If that infill bit isn't needed I might convert the .stl to an editable model and lose that bit. The only reason the bottom needs so much support is something to do with that round pin thing in the second picture. Guessing a spring goes on that but until I get the Makita battery apart...

First problem I can't find my T? security bit screwdriver to take the battery apart!

I got the .stl from here:

old makita battery swap to dewalt by jlguil

I've worked with makita for a very long time, and changed for dewalt.And I had this old worn battery laying here, I decided to use it to build removable dewalt to makita battery adaptor.

Printed in grey RS Pro PLA. I don't have a modern DeWalt battery & tool to compare it with but it appears to have a wafer thin "infill" section where my thumb is in the two pictures:

The pretty side:

The side that was supported:

If that infill bit isn't needed I might convert the .stl to an editable model and lose that bit. The only reason the bottom needs so much support is something to do with that round pin thing in the second picture. Guessing a spring goes on that but until I get the Makita battery apart...

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,127

- Location

- Sevenoaks, UK

I reckon the model for the DeWalt battery to Makita tool will need tweaking.

Because it's only screwed on one end it's "springy". I imagine the weight of a DeWalt battery, over time, might snap it. Maybe the guy who designed it uses a blob of CT1 or something? The adapter seems also to be a little recessed into the Makita top. Can't really see how the battery slides in. Hoping someone at work has a battery I can try before I see my mate.

Because it's only screwed on one end it's "springy". I imagine the weight of a DeWalt battery, over time, might snap it. Maybe the guy who designed it uses a blob of CT1 or something? The adapter seems also to be a little recessed into the Makita top. Can't really see how the battery slides in. Hoping someone at work has a battery I can try before I see my mate.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,127

- Location

- Sevenoaks, UK

I've slacked off from the DeWalt to Makita adapter. Waiting for a mate to send me a dead XR battery for measuring/trial fitting purposes.

Instead I'm now playing with a DeWalt battery to old Ryobi adapter. That was fun, measuring the curves!

Still need the XR battery mind.

Instead I'm now playing with a DeWalt battery to old Ryobi adapter. That was fun, measuring the curves!

Still need the XR battery mind.

Onoff

In the land of the unfinished project I am King!

- Messages

- 12,127

- Location

- Sevenoaks, UK

I must have ADHD!

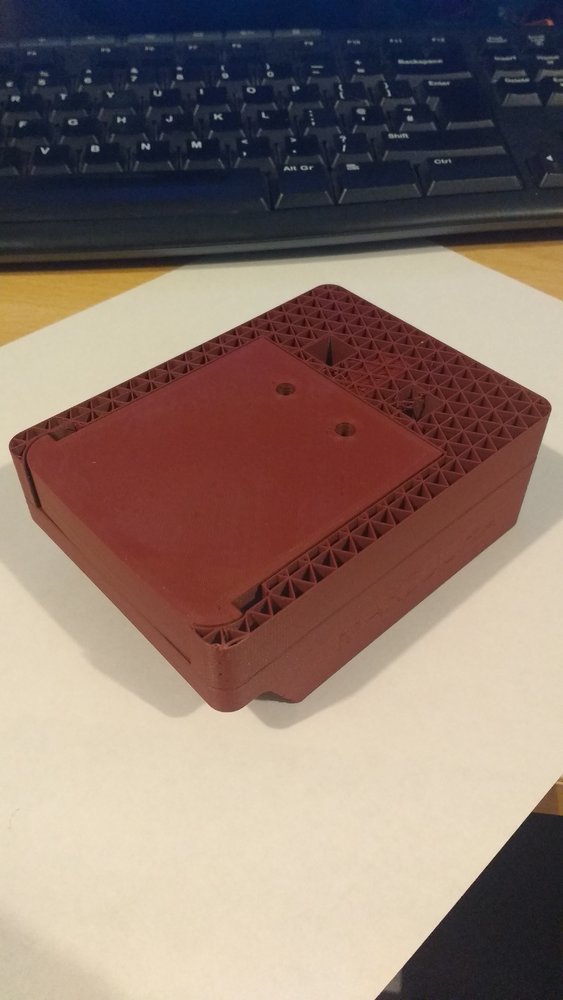

I've NEARLY finished the Makita battery to Duratool adapter and I think this one will be a winner. Printed in clay red PLA.

Printed this way up:

Supports:

The recessed name could have gone to 1mm deep, it's a tad shallow at 0.5mm:

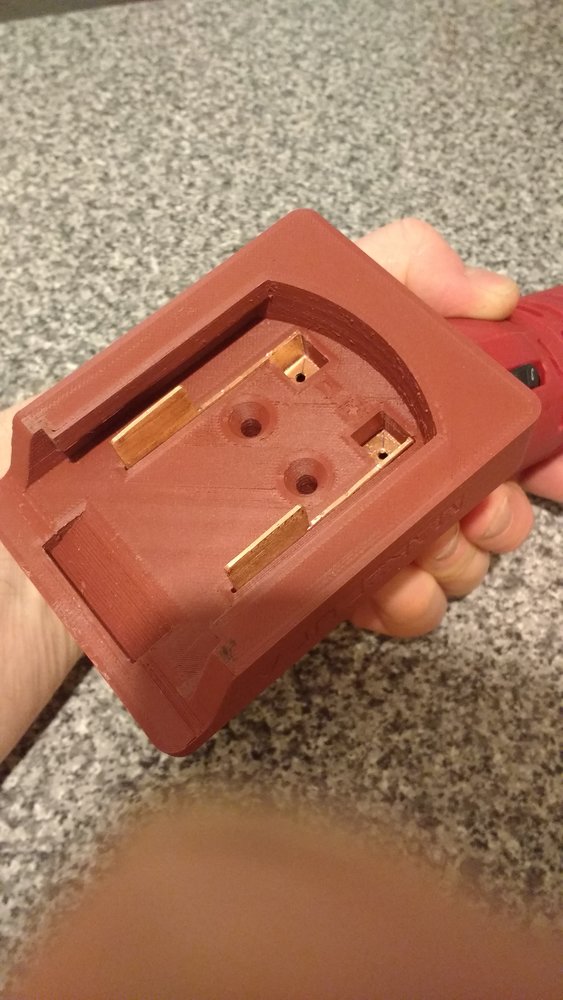

Hand fettled 1mm copper connectors:

They sit a fraction high which I could have avoided with a very slight change to the model. I reckon though, when I solder the wires on, I'll be able to push the connectors into the PLA:

I'll have to open the tool and solder on longer black & red wires:

It'll be permanently screwed to the tool with some bfo goldscrews. It'll only ever be used on Makita batteries. Picture of one of the copper connectors:

I'm going to try and publish it on Yeggi.

I've NEARLY finished the Makita battery to Duratool adapter and I think this one will be a winner. Printed in clay red PLA.

Printed this way up:

Supports:

The recessed name could have gone to 1mm deep, it's a tad shallow at 0.5mm:

Hand fettled 1mm copper connectors:

They sit a fraction high which I could have avoided with a very slight change to the model. I reckon though, when I solder the wires on, I'll be able to push the connectors into the PLA:

I'll have to open the tool and solder on longer black & red wires:

It'll be permanently screwed to the tool with some bfo goldscrews. It'll only ever be used on Makita batteries. Picture of one of the copper connectors:

I'm going to try and publish it on Yeggi.