indy4x

Forum Supporter

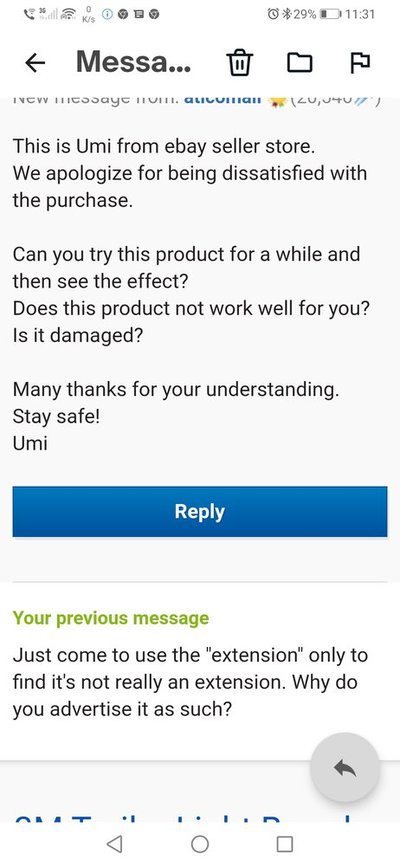

- Messages

- 3,609

- Location

- Pontypool, South Wales. UK

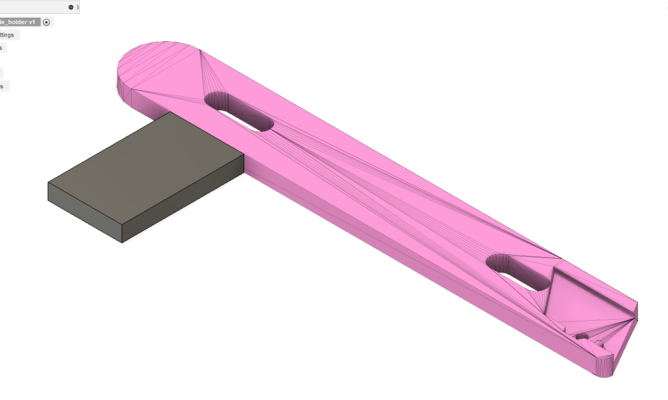

Yes, its for straightening brake pipesNot seeing any offsets. All those guides in a straight line?

Yes, its for straightening brake pipesNot seeing any offsets. All those guides in a straight line?

Nope, lifted it from Thingiverse after finding it on a YT videoDid you design the parts yourself?

It'll be interesting to see how it holds up, as it does look a bit thin for a 3D printed version. Especially since the print lines aren't in the optimal direction for the forces it'll see.

PLA, do have PETG but not played with it yetSurely the printed "fibres" are longitudinal to the tool so at their best orientation? Like when you bend a ruler.

Whatever, looks great in orange! What material?

Yes, its for straightening brake pipes

Can you post the STL please?

This particular design does not require the offsets - it's more of a gentle, multi pass tool.Thought so. That's not how it works. A pipe straightening tool actually distorts and manipulates the pipe before it finally comes out straight. As often as not, this helps work harden soft annealed materials but also, the wiggles and offsets help work out the bends or kinks.

The amount of distortion required is probably right up there with the amount of flex you're going to get with a weak plastic.

I hope you prove me wrong...

Cheers indy.

3/16" Tube Straightener by njmcpherson

The thru holes in the brackets get tapped to M8 after printing. The bearing wheels may need scaled up 0.5% if they are too tight of a press fit. The Bearings used are 608-2RS bearings (qty 16) and the bolts are M8X20mm Flat head bolts (quantity 16). The small washers go on each side of the...www.thingiverse.com

I wasn't having a dig but like the forum supporter 10er many of us miss the anniversary and are happy to pay. It just takes a minute for a member to post whilst the mods are busy anyway.@ukracer absolutely, if I draw something it usually get uploaded to Thingiverse, I did mean to include a link for this one but forgot at the time

This particular design does not require the offsets - it's more of a gentle, multi pass tool.

I would think this style work by skewing the roller axis relative to the pipe path. It relies on a good fit of the pipe in the roller - not sure you'll get that with 3D printed rollers.I think you'll find it does...

They will have a subtle offset (this one calls a "spiral") which manipulates the tube, even if it is already straight!

It is a small offset which is why the body needs to be rigid and why I wonder about the efficiency of a plastic version. I'm sure it will be fine on a perfectly coiled, annealed pipe but ideally it would work out any bends or kinks and to do that, it needs to manipulate the material with offsets in the rollers.

O

I would think this style work by skewing the roller axis relative to the pipe path. It relies on a good fit of the pipe in the roller - not sure you'll get that with 3D printed rollers.

I doubt it.Probably makes more sense in Chinese, ask Shang-Yuan Huang.

US20200101508A1 - Straightening device - Google Patents

A straightening device including: a plurality of rolling members, defining a first channel which is configured for a tubular member to pass therethrough, an extending direction of the first channel being transverse to at least one extending direction of at least one pivot of at least one of the...patents.google.com

The file is on this page .. https://www.mig-welding.co.uk/forum/threads/handy-3d-prints-for-the-workshop.97647/page-18I'll admit, that despite having done quite a bit of mesh manipulation in Fusion this year, I've not had any reason to do it since the big update for mesh.

If you can send me a link to the stl, I'll have a play tomorrow.